Advantages of vacuum forming

The technology is most often used for series production ranging from hundreds of pieces per year to tens of thousands of pieces per year.

Technology and specifics of vacuum forming

MOST COMMONLY USED MATERIALS

ABS, ABS/PMMA, PE, HIPS, PS/PE, PMMA, PET, PETG, PC, PVC etc.

blends based on PC, PE, PS, PMMA – e.g. PS/PE or ABS/PMMA

filled and non-combustible materials, regenerates of all materials

Part SIZE

Up to 3 × 2 metres with a wall thickness of 1 to 10 mm

OTHER OPERATIONS

CNC cutting, welding, gluing

THE MOST COMMON APPLICATIONS

automotive, construction machinery, garden equipment, lighting equipment, technical covers

VF technology

We recommend vacuum forming especially for smaller and medium series production, preferably with final surface treatment, i.e. with a defined colour, pattern or surface quality at the paint level.

An advantage of vacuum forming is the low costs of development, construction and production tools, as well as very short start-up times. This advantage predetermines this technology for all fields where frequent changes in product design are required with a relatively high quality of production.

How does vacuum forming work?

The principle of the technology consists of heating the semi-finished plastic sheet to the forming temperature. This sheet is imprinted on the mould or into the mould while the perfect imprint is made using vacuum applied between the plate and the mould.

After forming the part shape, the part is machined on a 5-axis CNC unit. Using this device, precision parts can be made with a number of holes and shapes, with maximum reproducibility guaranteed.

If the type of application of the part so requires, parts can be welded or glued or assembled into larger units.

Colour and shape options

For very small series production and specific colour requirements, we can also paint parts according to customer requirements. Usually, however, the parts produced by vacuum forming are already produced in the desired colour and design.

Moulds used for the production of parts are most often made of aluminium (cast moulds or machined moulds). For prototype parts, it is possible to use moulds from cheaper materials such as MDF.

The materials used for vacuum forming are thermoplastics.

Our products have been used for the following applications

HIGH QUALITY SURFACE (PMMA) PRODUCTS

In colour and metallics

WE SUPPLY PRODUCTS MADE OF GLOSS MATERIALS WITH PE COVER FOIL

PRODUCTS WITH DESIGN SURFACE OR IN MATT DESIGN

At Promens Zlín, we also offer a combination of vacuum forming with other technologies.

An example is the combination of vacuum forming and PU-foam forming in two product modifications.

Examples of possible combinations of technologies

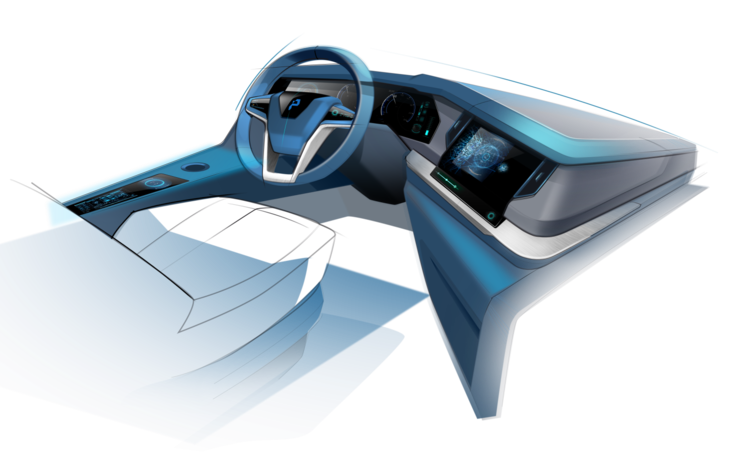

EXAMPLES OF SOFT PARTS (E.G. DASHBOARDS)

- vacuum shaped dashboards

- low density PU foam

- reinforcement

EXAMPLES OF RIGID STRUCTURAL PARTS

- vacuum formed ABS, PC

- high density PU foam

These parts are manufactured in two ways – in a two-part design or as a sandwich, where the third layer is also a vacuum part.

Tailor-made applications

We develop, manufacture and supply parts for major manufacturers throughout Europe.

At Promens Zlín, we choose a combination of technologies according to efficiency, seriality, material and production price according to the required cost / performance ratio.

As a standard, we also address the requirements of Advanced Logistics. Our advantage is that after R&D and production we can supply parts assembled into Just in Time assembly units. We are a partner for manufacturers and for Just in Sequence deliveries.

With these solutions, we help customers be successful in the market.

We work for the best

Photos from production

RESEARCH AND DEVELOPMENT | PRODUCTION | PAINTING | ASSEMBLEMENT | JUST IN TIME & JUST IN SEQUENCE

We are experienced Tier 1 development suppliers.

Together, we will make your project succeed.

Call Us

+420 577 051 154

Mail Us

zlin.sales@promenszlin.com