“Our people set plastics in motion and turn our partners’ visions into reality.”

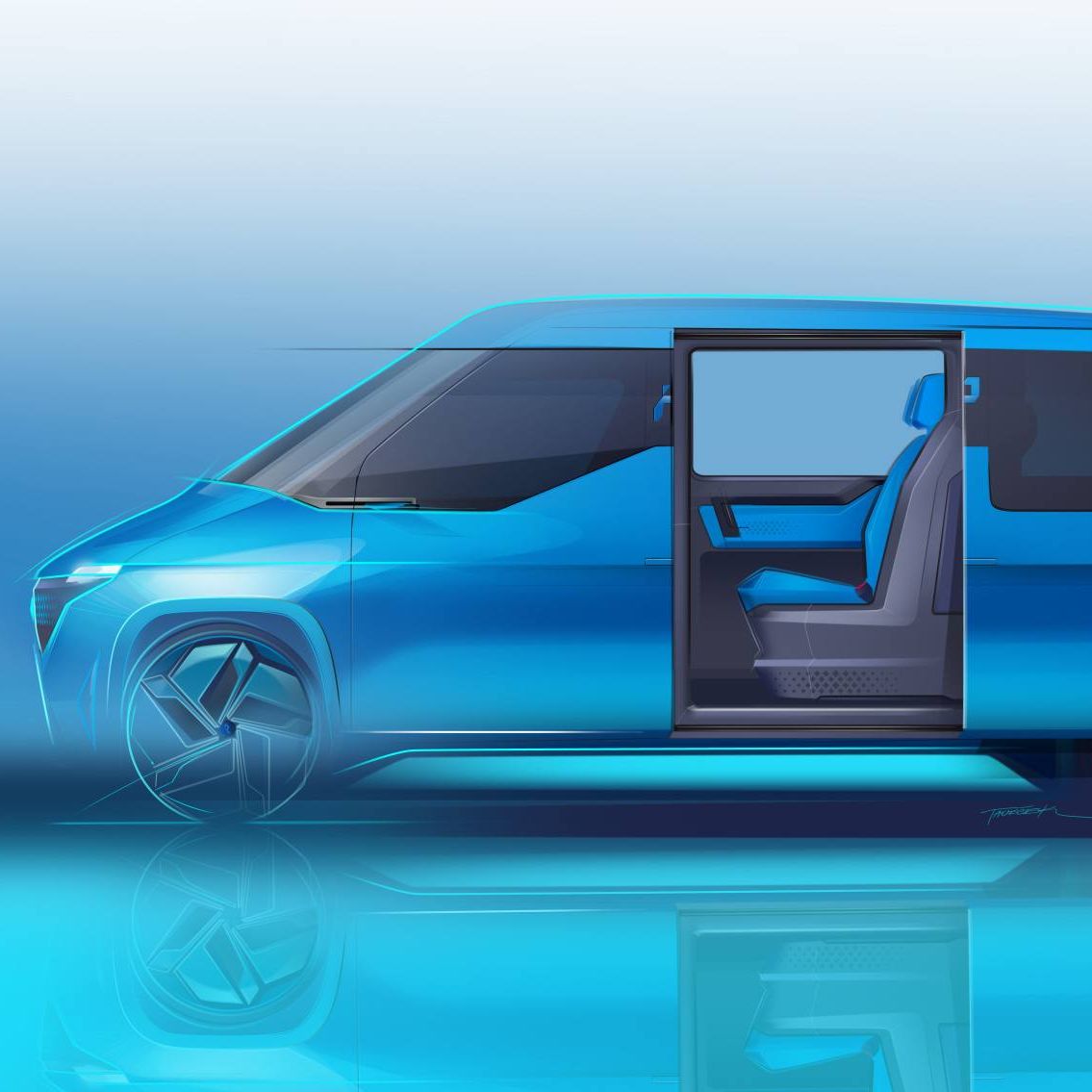

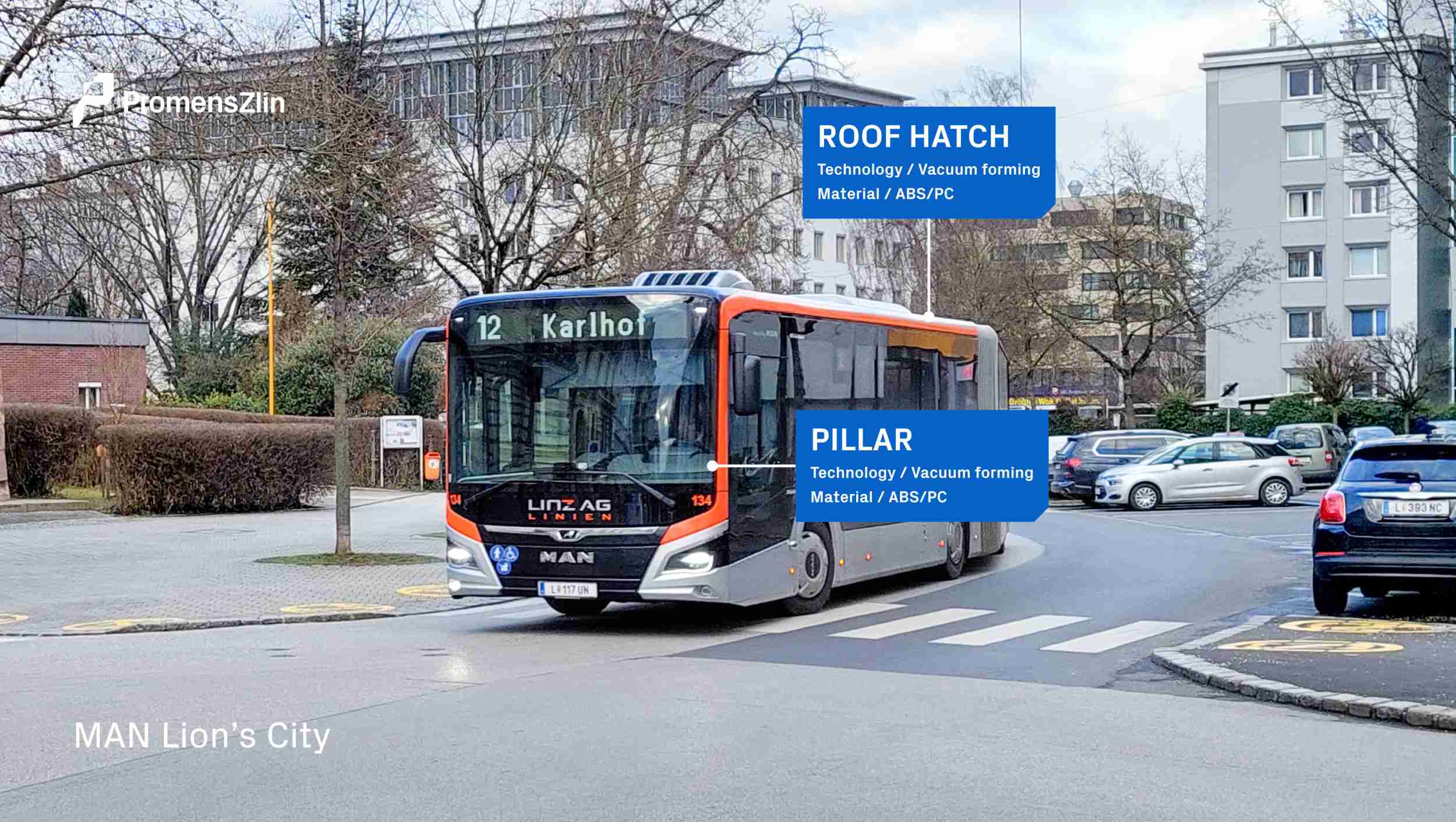

For bus manufacturers, Promens Zlín is one of the most sought-after suppliers due to the comprehensive range of technologies we have at our disposal for the production of plastic parts – RIM and PU-RIM, vacuum forming and SMC.

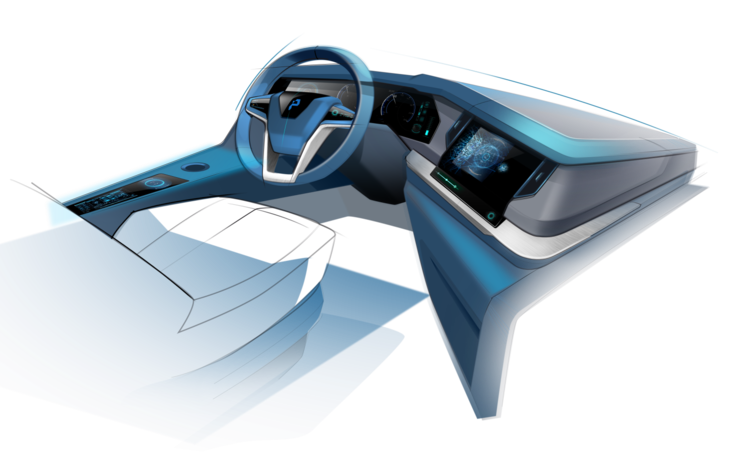

We can arrange construction design and production of a single part up to a complete solution for the driver’s compartment.

Tractors, combine harvesters, mini tractors and other machinery and equipment.

RIM technology and vacuum forming are suitable solutions for many applications such as complete engine hoods, fenders, roofs, interior parts and more.

Loaders, dumpers, vibratory rollers, excavators and other machinery and equipment. We are well aware of the demands in this segment.

Mechanical properties, temperature resistance, visual demands, serial production, variability and other challenges. We have extensive experience in this field, whether it concerns the production of individual parts or complex assemblies and functional units.

Acceleration, lower consumption, better ergonomics. We help customers to increase the efficiency of each truck.

Speed, less aerodynamic drag and noise and passenger comfort.

Our development and production of parts for modern trains and trams shortens distances and increases the attractiveness of public railway transport.

We have more than 20 years of experience in the design, development and production of rear spoilers using PU-RIM technology, which is a suitable solution for medium-series projects. We always approach these comprehensively.

Supplying the solution includes the design of suitable packaging, construction and production of all tools. We will supply the product, including the surface treatment, in the appropriate quality and the required range of colours.

We will finalize the construction of the part, including the appropriate assembly solution, reinforcement or incorporation of functions such as, for example, brake lights or washer nozzles.

We also have unique experience in the NVH field of engine covers, the insulation properties of which meet the premium vehicle requirements of the world manufacturers. For this, we use a special production line and robotic workplaces with a capacity of up to 300,000 pieces per year.

We work for the best

Discover stories of successful collaborations with partners from the automotive, medical, and other industrial sectors. Our case studies showcase how we use top-quality plastic parts and enclosures to deliver effective solutions for diverse technical challenges.

Through close partnerships with clients, we provide reliable, customized solutions that meet the highest standards of quality and performance.

Explore how we’ve helped our partners achieve success – and see what we can do for you.

RESEARCH AND DEVELOPMENT | PRODUCTION | PAINTING | ASSEMBLEMENT | JUST IN TIME & JUST IN SEQUENCE

Plastic parts and assemblies for the automotive industry